Cp Pumps systems

As an innovator in the field of highly complex centrifugal pumps, CP Pumpen AG has been pursuing one objective for decades: to make industrial processes, which pump hazardous or valuable fluids, even more efficient, sustainable and safe – for the installations themselves, for the employees and for the whole environment.

The core competences of CP Pumpen

- Developing, manufacturing and distributing efficient, safe and rugged centrifugal pumps

- Designing and engineering chemical process pumps

- Comprehensive expertise in the field of high-quality materials such as stainless steel, special alloys, fluorinated polymers and ceramic

- Competent advice about pumps and pump systems

- Manufacturing and holding stocks of original pump spare parts

- Strategic material purchasing from selected suppliers

- First-class pump assembly

- Comprehensive pump testing

- Efficient logistics

- Quality control/management

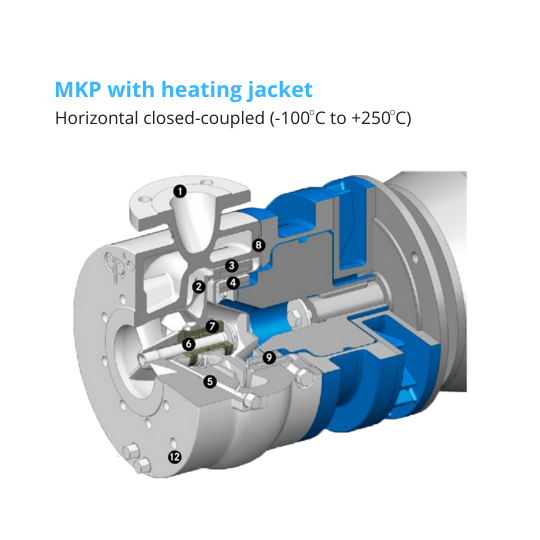

MKP – Stainless Steel Magnetic Drive Chemical Process Pump

Special features :

Up to 30 % solids and 1 mm particle size can be pumped – depending on the nature of the particles*

Heatability

- single-part heating chamber system

- very efficient heatability

- only 1 entrance and 1 discharge connection

- simple & easy to heat, a single heating jacket reduces installation costs

- low temperature difference in the pump & no cold zones thanks to excellent heat distribution

- short heating up time due to high thermal transfer efficiency & direct feed of the heating energy into the fluid space

Construction

- unique drive and bearing concept

- compact & virtually free of dead space

- bearing frame & monoblock design

- no shaft feedthrough & leak-free

- low product content

- no plain bearing carrier, no rotating shaft

- single-part & central bearing, on all sizes

- horizontal & vertical installation possible

- low bearing forces due to hydraulically balanced impeller

- internal & external bearing lubrication options

- high material flexibility (casing, impeller as well as plain bearing materials)

- eddy-current-free shroud possible (reduced energy consumption)

- inverted drive principle at flow rates up to approx. 200 m3/h

Construction

- unique drive and bearing concept

- compact & virtually free of dead space

- bearing frame & monoblock design

- no shaft feedthrough & leak-free

- low product content

- no plain bearing carrier, no rotating shaft

- single-part & central bearing, on all sizes

- horizontal & vertical installation possible

- low bearing forces due to hydraulically balanced impeller

- internal & external bearing lubrication options

- high material flexibility (casing, impeller as well as plain bearing materials)

- eddy-current-free shroud possible (reduced energy consumption)

- inverted drive principle at flow rates up to approx. 200 m3/h

Assembly & repair

modular system made up of few individual parts.

assembly friendly

Standard

DIN EN ISO 2858, 5199, 15783

Directives

EC Machinery Directive

EC Atex Directive

In general, media with solids content can be transported, but application-specific verification in advance is absolutely necessary

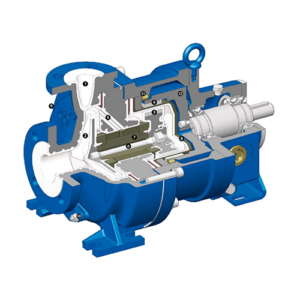

MKP-S – Stainless Steel Self-Priming Magnetic Drive Chemical Process Pump

Special features

- Suction tank integrated in the casing (=high operating safety)

- Self-priming with a suction head of up to 8.5 m

- Suitable for efficient unloading of tanks (tanker trucks) with no outlet on the tanker floor

Construction

- compact & virtually free of dead space

- no shaft feedthrough & leak-free

- single-part & central bearing

- low bearing forces due to hydraulically balanced impeller

- internal & external bearing lubrication options

- high material flexibility

- eddy-current-free shroud possible ( reduced energy consumption)

- inverted drive principle

Construction

- compact & virtually free of dead space

- no shaft feedthrough & leak-free

- single-part & central bearing

- low bearing forces due to hydraulically balanced impeller

- internal & external bearing lubrication options

- high material flexibility

- eddy-current-free shroud possible ( reduced energy consumption)

- inverted drive principle

- 1:-Pump casing with PFA lining

- 2:-Impeller

- 3:-Inner magnet assembly (on product side)

- 4:-Outer magnet assembly (on atmospheric side)

- 5:-Internal bearing lubrication or external flush connection

- 6:-Single bolt with waisted shank to fasten the rotating unit

- 7:-Plain bearing assembly

- 8:-One-piece, vacuum-resistant, non-metallic containment shell

- 9:-Pt100 temperature probe on casing

- 10:-Casing drain

- 11:-Bump ring

- 12:-Flywheel

Heatability

heating possible

Assembly & repair

modular system made up of few individual parts

assembly friendly

Standard

DIN EN ISO 2858, 5199, 15783

Directives

EC Machinery Directive

EC Atex Directive

In general, media with solids content can be transported, but application-specific verification in advance is absolutely necessary

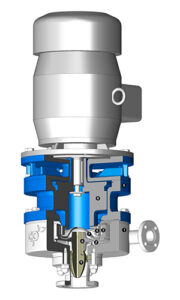

MKTP – Stainless Steel Magnetic Drive Chemical Process Sump Pump

Special features

- Sump pump for submersion depths down to 4 m.

- Ball bearings that can be lubricated externally as an option (with patent)

- Ideal for unloading tanks with no outlet on the tank floor

- Can be combined with injector for unloading larger containers as a tank unloading system

- Solids possible*

- Sophisticated bearing flushing offers reserves for difficult applications and high solids concentration in fluids

- Corrosive/toxic media are pumped in total safety (without fluid and vapours escaping into the environment)

Construction

- compact & virtually free of dead space

- no shaft feedthrough & leak-free

- single-part & central bearing

- no plain bearing carrier

- eddy-current-free shroud possible ( reduced energy consumption)

- low bearing forces due to hydraulically balanced impeller

- product-lubricated bearing eliminates common weak point on sump pumps

- inverted drive principle

Construction

- compact & virtually free of dead space

- no shaft feedthrough & leak-free

- single-part & central bearing

- no plain bearing carrier

- eddy-current-free shroud possible ( reduced energy consumption)

- low bearing forces due to hydraulically balanced impeller

- product-lubricated bearing eliminates common weak point on sump pumps

- inverted drive principle

Heatability

available with double-wall heatable discharge pipe

Assembly & repair

modular system made up of few individual parts

assembly friendly

Standard

DIN EN ISO 2858, 5199, 15783

Directives

EC Machinery Directive

EC Atex Directive

In general, media with solids content can be transported, but application-specific verification in advance is absolutely necessary

MKPL – PFA Lined Magnetic Drive Chemical Process Pump

Special features

- metal reinforcement with thick, vacuum-tight, corrosion and diffusion-resistant PFA lining

- 100 % vacuum tight

- PFA-lined plain bearing carrier

- medium temperature up to 200°C max.

Construction

- compact & virtually free of dead space

- no shaft feedthrough & leak-free

- single-part & central bearing

- horizontal installation

- open impeller & closed impeller with metal core

- bearing made of pure SSiC (highest operating safety)

- plain and thrust bearings secured with polygonal form-fit, self-centring anti-rotation devices

- plastic impeller firmly secured against rotating in the wrong pump direction

- single-part, vacuum-tight, non-metallic shroud

Assembly & repair

bearing frame and motor can be dismantled (pump remains in the facility and is sealed to the outside)

modular system made up of few individual parts

assembly friendly

Standard

DIN EN ISO 2858, 5199, 15783

Directives

EC Machinery Directive

EC Atex Directive

MKP Bio - Stainless Steel Magnetic Drive Biotech Process Pump

Special features

- 100 % drainable (no flushing, drain or ventilation connections

- 100 % cleanable (CIP)

- 100 % sterilisable (SIP)

- self-venting

- parts in contact with medium: Surface quality Ra ≤ 0.8, inside edges R3, surfaces inclined > 3°

Construction

- compact & virtually free of dead space

- no shaft feedthrough & leak-free

- single-part & central bearing

- vertical installationno shaft seal (=no penetration by micro-organisms)

- no plain bearing carrier

- single-part, centrally arranged impeller bearing with optimal cooling and flushing (=optimal running properties)

- low bearing forces due to hydraulically balanced impeller

- high material flexibility

- inverted drive principle

Assembly & repair

modular system made up of few individual parts

assembly friendly

impeller can be removed without tools

Standard

DIN EN ISO 2858, 5199, 15783

DIN EN 12462

Directives

CIP

SIP

EHEDG

EC Machinery Directive

EC Atex Directive

FDA + EU 1935/2004

Hygiene standards 3A