Cellulose Filter Paper

- Food and Beverages

- Chemical-Pharmaceutical

- Cosmetics and Perfumes

- Surface Treatment

The Cellulose filter pads are manufactured from pure, specially selected and treated virgin cellulosic fiber. Addition of special food grade resins increases the wet strength of the pads which is very important for filtration of water based products. This pads also helps to reduce edge leakage to a minimum – achieved through the special filter sheet formulation and processing conditions. The basic components of filter pads, cellulose and filter aid, are natural products which have a wide range of compatibility.

These filtration sheets are widely used in the filtration of products where they give outstanding clarity and stability combined with long sheet life and integrity. These filters provide long life & clarity are essential. Similarly these products have found wide acceptance in the filtration of syrups for soft drink, gelatins, cosmetics plus a diverse spread of chemical & pharmaceutical intermediates & final products.

All Sawant Filtech Cellulose Filter Media is FDA® recognised

- Rapid, Medium or Slow Filtration

- Low ash content <0.01%

- High resistance in humid state

- Gravimetric analysis

- Cotton and a-cellulose fibers.

- Choose between a variety of diameters

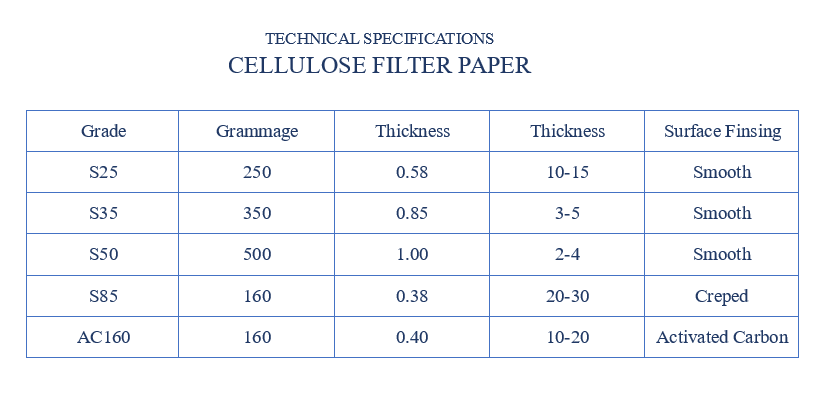

Technical specifications

SAWANT FIltech Provides laboratory technicians and with a complete range of filter paper without ash for all types of quantitative analysis.

When burning paper, ash is obtained with a proportion of 0.01%, thus complying with international rules in this area. For the manufacturing of this paper high quality cellulose is used.

Once the paper is manufactured, it is treated with acid and washed with demineralised water. It’s great resistance when wet makes it ideal for use in Büchner filtrations.

- Available in many different formats

- Smooth or rough services

- Better filtration results

- You choose the filtration speed

- Choose between a variety of diameters

- Retention from 2 µm up to 50 µm

- Cotton and a-cellulose fibers