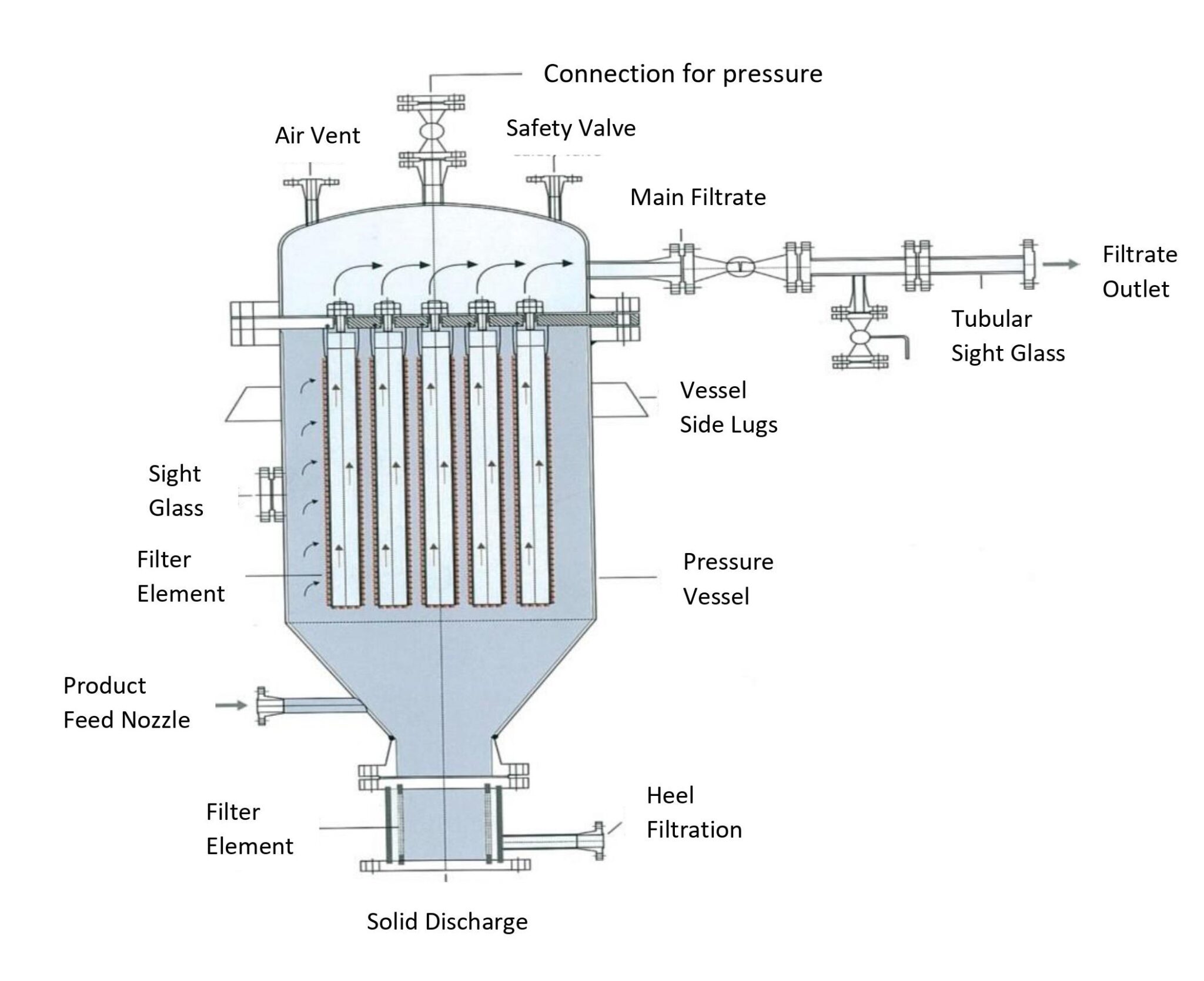

MULTI TUBE FILTER

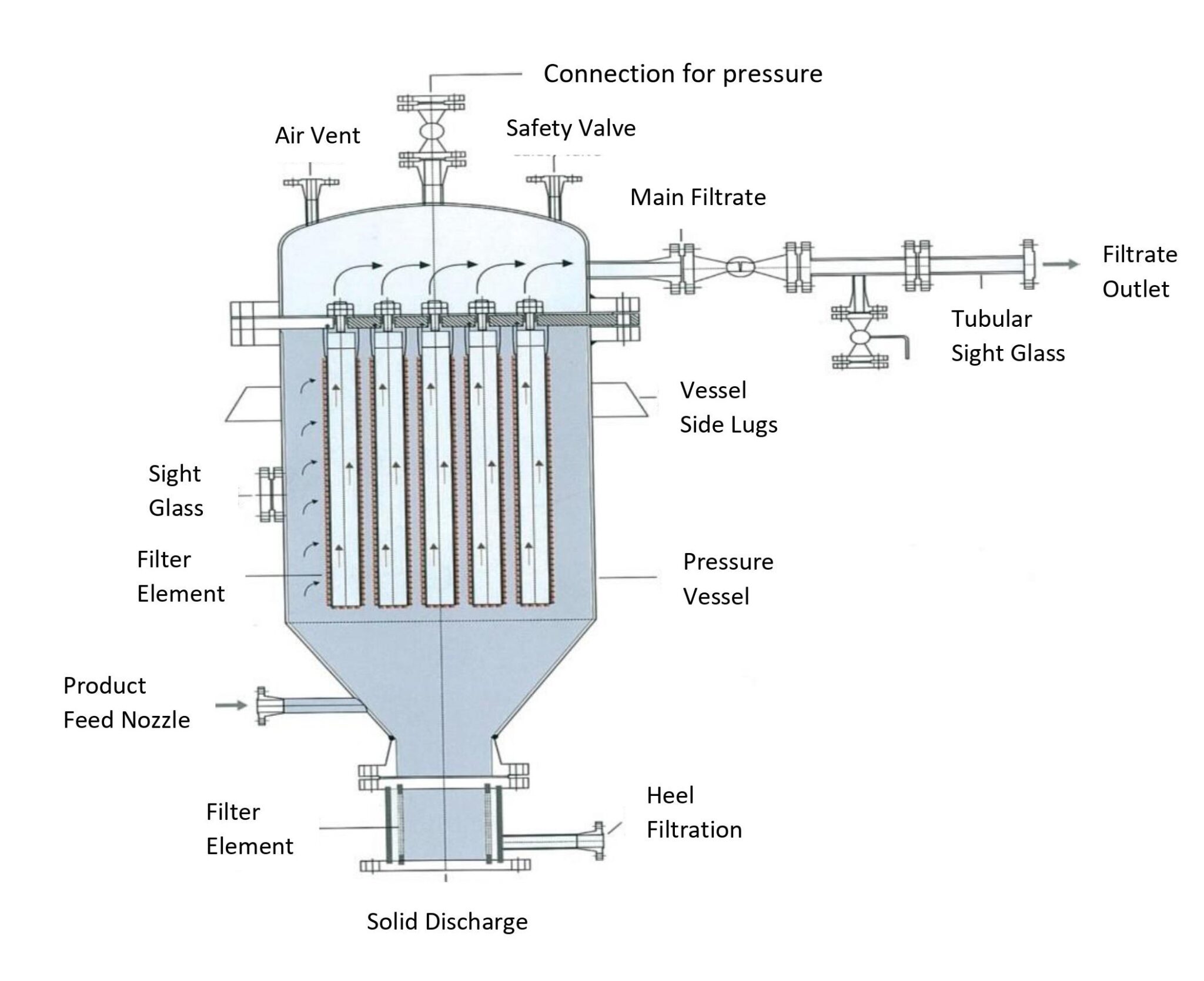

Filtration elements are made up of multi tubes and dressed with a seamless filter cloth to obtain clear filtrate. The multi tubes filter are housed in the pressure vessel vertically using either tube sheet design or internal register design.

- Sawant Filtech has specially designed a system to minimise the hold up

- Filter elements available MOCs- PP, PVDF, PTFE, PFA, Sintered

- Catalyst recovery filter PD, Ra-ni, Pt etc

- All pressure vessels are designed under ASME Code

- Candles are arranged vertically inside a pressure vessel

- The No. of candles decides the filtration area of the filter

- Construction of filter element is with Hexa perforated tube with centre rising tube closed at bottom and provided with outlet at top

- Circulation & Filtration is regulated from outside to inside and clean liquid

Applications

- API & Pharma Industry

- Activated carbon application in API

- Catalyst recovery filtration in hydrogenation

- Edible oil filtration

- Food & sugar industry

- Waste water and process water treatment

- Poly Oils

- Phosphate

- Viscose fibres

- Filtration in bio-diesel plants

- Caffeine plant extract

Applications

- API & Pharma Industry

- Activated carbon application in API

- Catalyst recovery filtration in hydrogenation

- Edible oil filtration

- Food & sugar industry

- Waste water and process water treatment

- Poly Oils

- Phosphating

- Viscose fibres

- Filtration in bio-diesel plants

- Caffine plant extract

Features

- CIP is possible with high pressure rotating nozzle

- High operational safety as contact of toxic and hazardous chemicals is avoided due to closed operation to surrounding closed operating plant

- Highest recovery of the noble metal catalyst in hydrogenation reaction

- Cake discharge in close system possible with automated butterfly valve at drain nozzle, hence clean room specification is observed

- Variety of filter mediums available

- Very high filtrate clearity

- Recovery of valuable product possible with efficient washing with pressure gradient and diffusion

- Closed system ensures hermatic sealing hence degradation due to oxidation is avoided

Filter media/Element

- Designed to maintain high filtration rates without blinding the fabric

- Minimal backwash required for cake release

- Consistent retention of particles

- Design for easy installation and through cleaning

- Compatible filter media available for various solvents/fluids

- Filter media optimized for efficient builtup and retention of solid cake

Filter media/Element

- Designed to maintain high filtration rates without blinding the fabric

- Minimal backwash required for cake release

- Consistent retention of particles

- Design for easy installation and through cleaning

- Compatible filter media available for various solvents/fluids

- Filter media optimized for efficient builtup and retention of solid cake

Material of construction

- Stainless Steel 304

- Stainless Steel 316

- Stainless Steel 316L

- Stainless Steel 904 L

- Monel Metal Nickel

- Hastelloy

- Polypropylene (PP)

- Polyvinylidene Fluoride (PVDF)

- Polytetrafluoroethylene (PTFE)

- Perfluoroalkoxy Alkane (PFA)

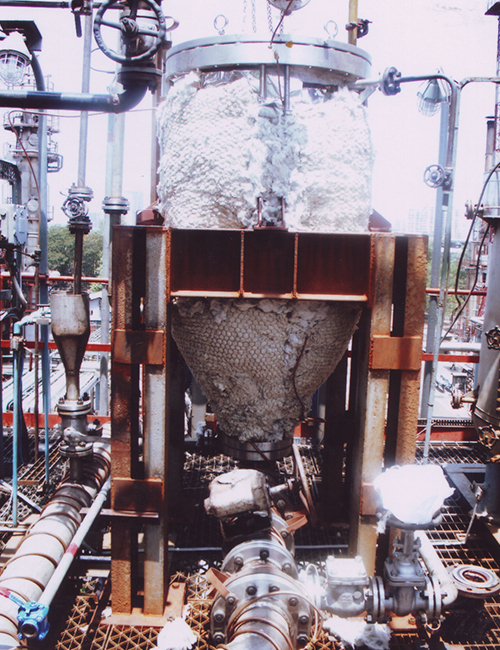

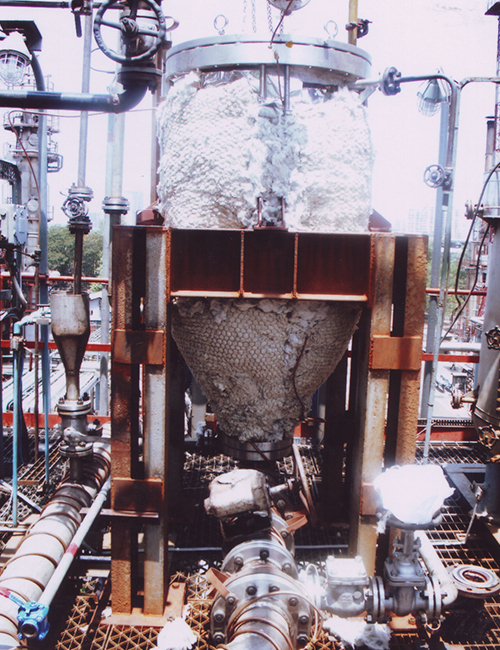

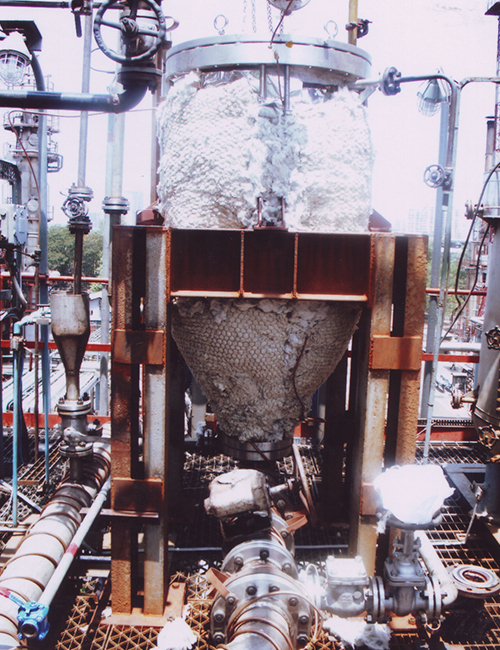

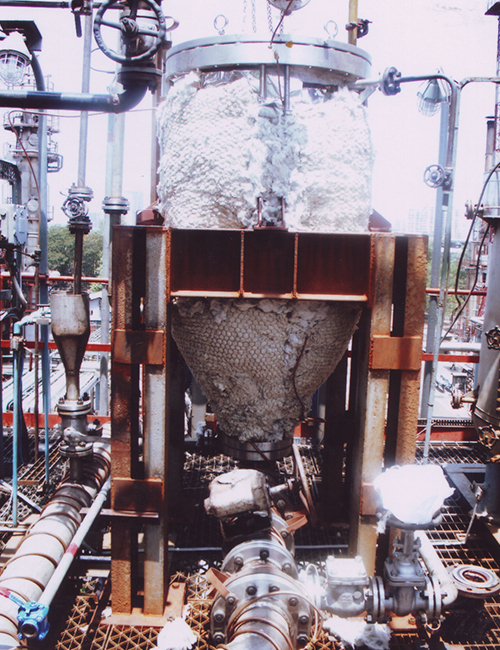

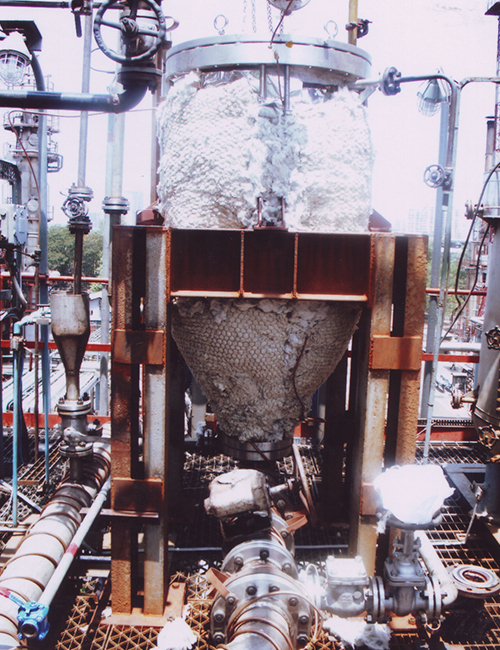

Catalyst Filtration & Recovery

Sawant Filtech offers a complete isolated system for catalyst filtration and recovery. Most of the catalysts used in the industries are pyrophoric in nature thus handling and operating these catalysts has to be done in a closed isolated environment.

Our catalyst filtration systems are manufactured with highest safety standards and ensure total recovery of catalyst.

- Sawant Filtech has specially designed a system to minimise the hold up

- Available in SS 316,SS 316L, SS 904L, Monel metal nickel, Hastelloy, PFA Coated, HALAR Coated

- Filter elements available MOCs- PP, PVDF, PTFE, PFA, Sintered

- Catalyst recovery filter PD, RA-NI, PT Etc

- All pressure vessels are designed under ASME Code

- Candles are arranged vertically inside a pressure vessel

- The No. of candles decides the filtration area of the filter

- Construction of filter element is with Hexa perforated tube with centre rising tube closed at bottom and provided with outlet at top

- Circulation & Filtration is regulated from outside to inside and clean liquid

Catalyst Filtration & Recovery

Sawant Filtech offers a complete isolated system for catalyst filtration and recovery. Most of the catalysts used in the industries are pyrophoric in nature thus handling and operating these catalysts has to be done in a closed isolated environment.

Our catalyst filtration systems are manufactured with highest safety standards and ensure total recovery of catalyst.

1] Sawant Filtech has specially designed a system to minimise the hold up.

2]Available in SS 316,SS 316L, SS 904L, Monel metal nickel, Hastelloy, PFA Coated, HALAR Coated.

3]Filter elements available MOCs- PP, PVDF, PTFE, PFA, Sintered.

4]Catalyst recovery filter PD, RA-NI, PT Etc

5]All pressure vessels are designed under ASME Code.

6]Candles are arranged vertically inside a pressure vessel.

7]The No. of candles decides the filtration area of the filter.

8]Construction of filter element is with Hexa perforated tube with centre rising tube closed at bottom and provided with outlet at top.

9]Circulation & Filtration is regulated from outside to inside and clean liquid.