THE COMPANY JET SOLUTIONS SA

The company JetSolutions SA was created in 2002 by two engineers, Mr. Daniel Leva and Mr. Patrick Mayor.

The company currently employed twenty high qualified personnel in the powder and liquid handling domain.

The company currently employed twenty high qualified personnel in the powder and liquid handling domain.

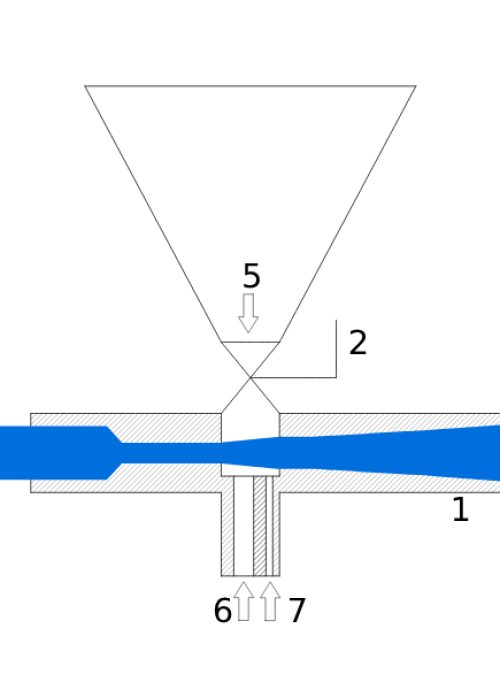

Principle of function of the injector (system Venture)

The pump creates the pressure before the injector, by the change of section; the speed of the

liquid is getting higher and creates a vacuum through the Venture effect. This enables the mixture

of the powder or a liquid with the conveyed liquid. When the inlet powder valve is open, the powder

will be introduced particle by particle and directly dissolved into the liquid. The choice of the pump

depends on the required transfer time as well as on the viscosity of the end product

- Large jet feed injector

- Powder valve

- Direction of the flow

- Outlet of the mixture

- Powder inlet

- Liquid inlet

- Inlet for small quantities

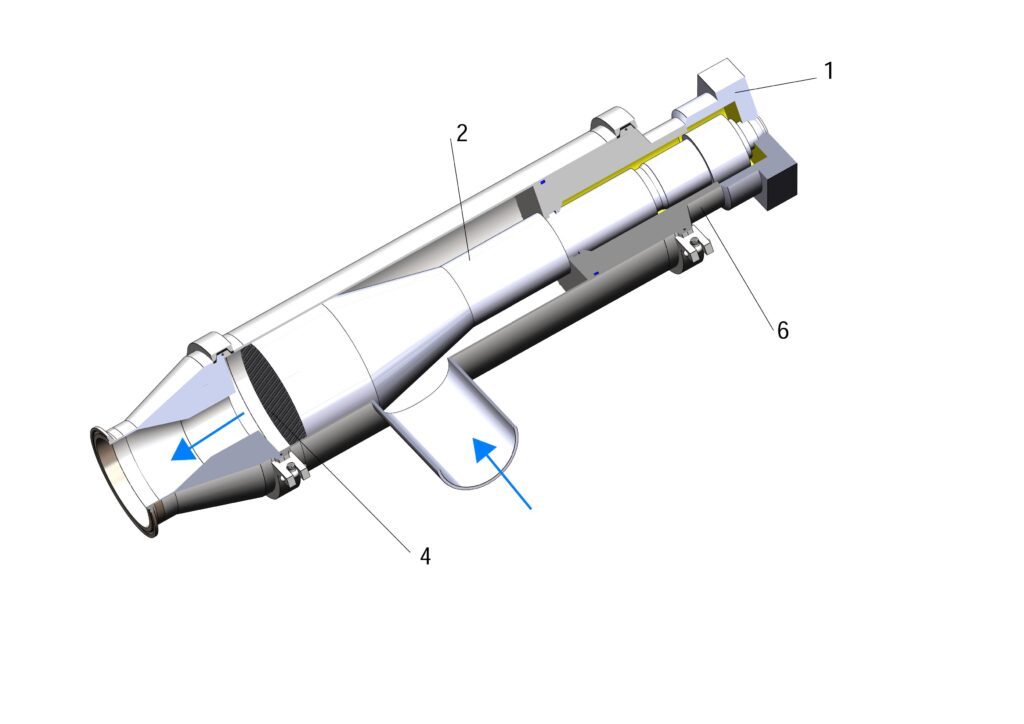

Function of the homogenizer

The VTR homogenizer enables a fluid, a suspension or an emulsion to be homogenized or dispersed

under the best conditions. It can be operate to max. pressure of 12 bar.

- The adjustment of the gap (4) of the homogenizer can be done continuously by adjustment screw (1) to a predefined dimension (possibility to adjust the gap during production). A graduation on the screw

- (1) and on the housing (6) enables to obtain the desired adjustment. 1 division on the screw (1) corresponds to 0.1 mm. The gap between the stroke on the housing (6) is of 1 mm. Due to the speed acceleration (A) in the tube of high turbulences (1). The product is conveyed into the homogenising zone (B) and transferred through the particle reducer (2). Thanks to the high velocity, the high turbulences create a homogenous solution.