Famat Sampling SA

Famat is a Swiss engineering company for 40 years in the development and manufacturing of valves applications for projects in:

- Chemical

- Fine Chemical

- Pharmaceutical

- Cosmetics

- Food

- Petrochemical

- Founded in 1974, FAMAT is certified ISO 9001-2015. Its procedures guarantee the best services in compliance and on-time deliveries with most industries standard.

- The company has renewed some partners, won new key accounts and is working on implementation of new ranges of products.

- For the Pharmaceutical, Bio-technological and Chemical industry, FAMAT has supplied for years a complete range of sampling now transferred to a Swiss Sampling expert company, BIAR SA and its new branch called FAMAT Sampling.

- FAMAT has today offices, distributors and agents in most major countries in Europe, Middle-East, Asia and America. This global network allows us a close cooperation with our customers and end-users, to guarantee a full satisfaction at all levels of the supply chain.

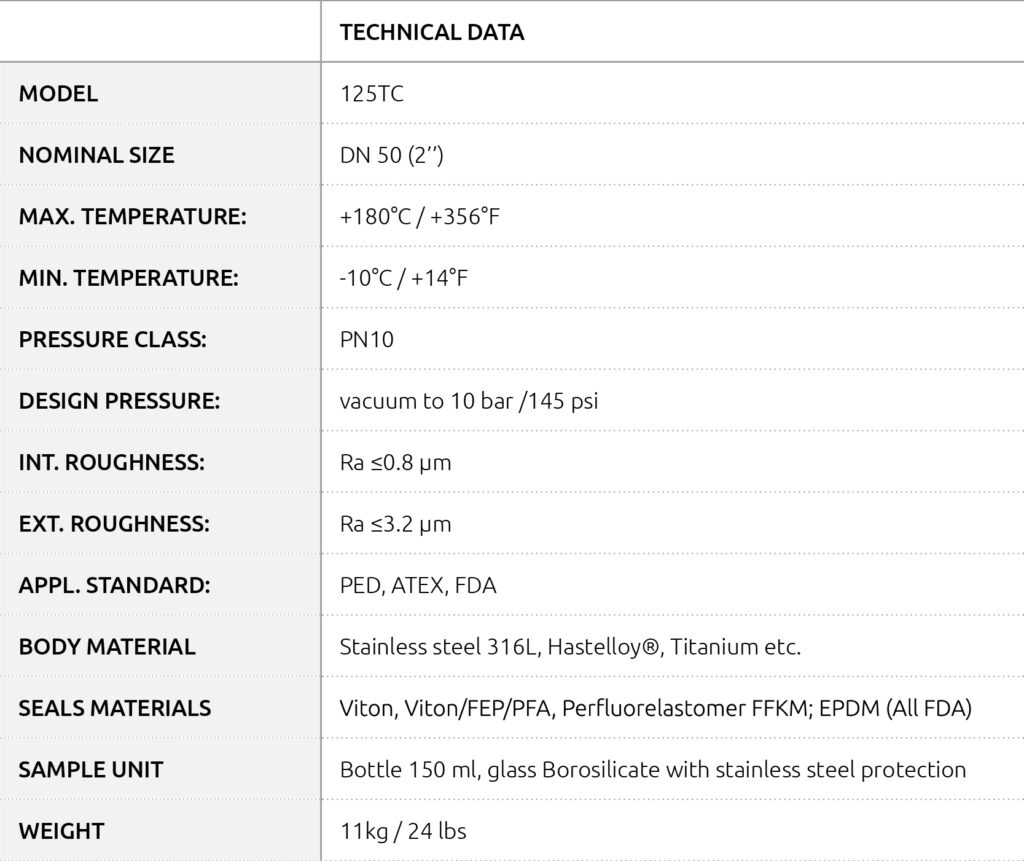

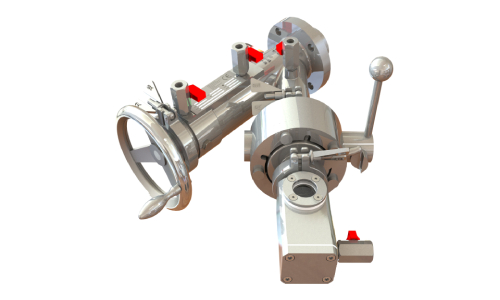

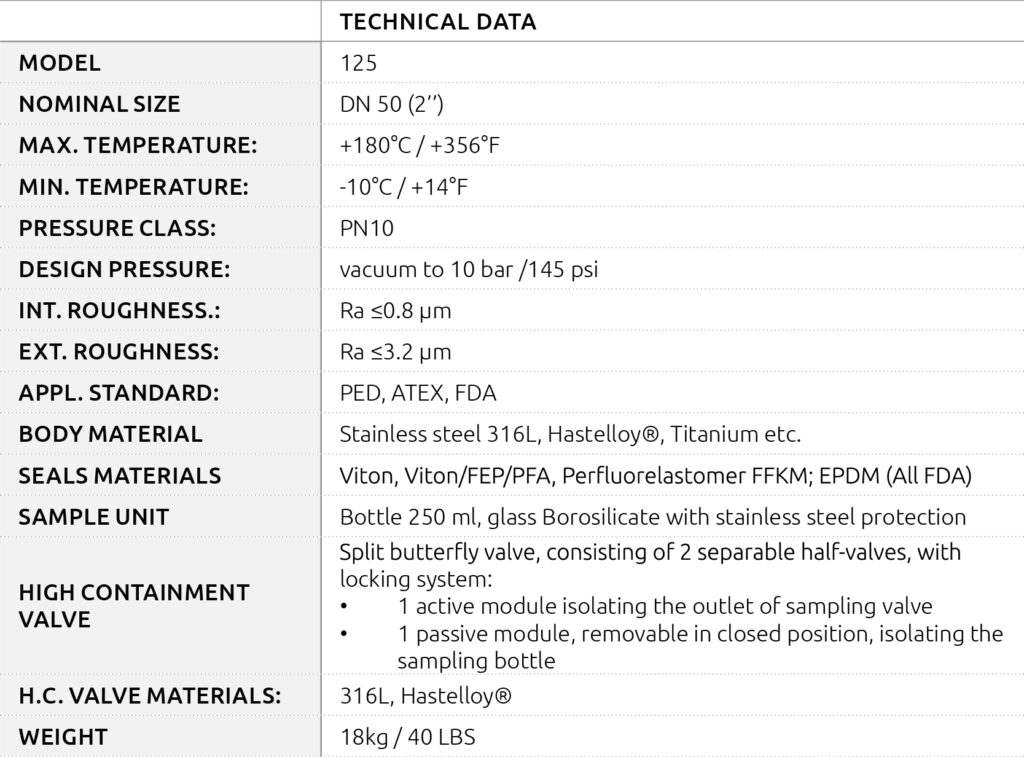

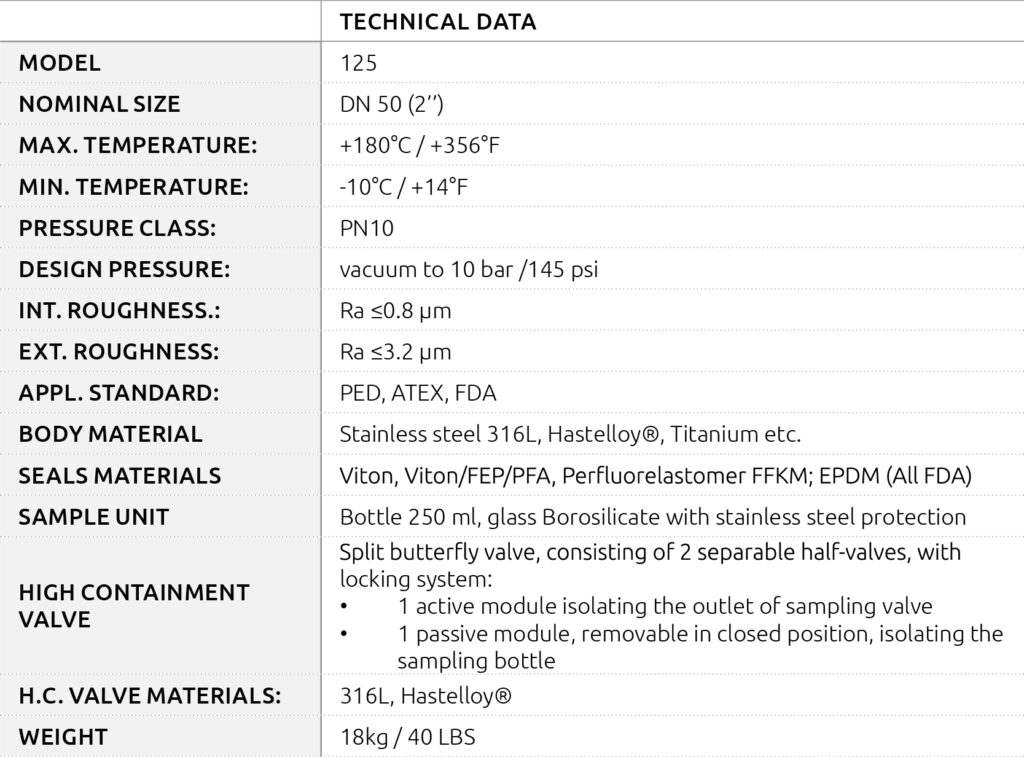

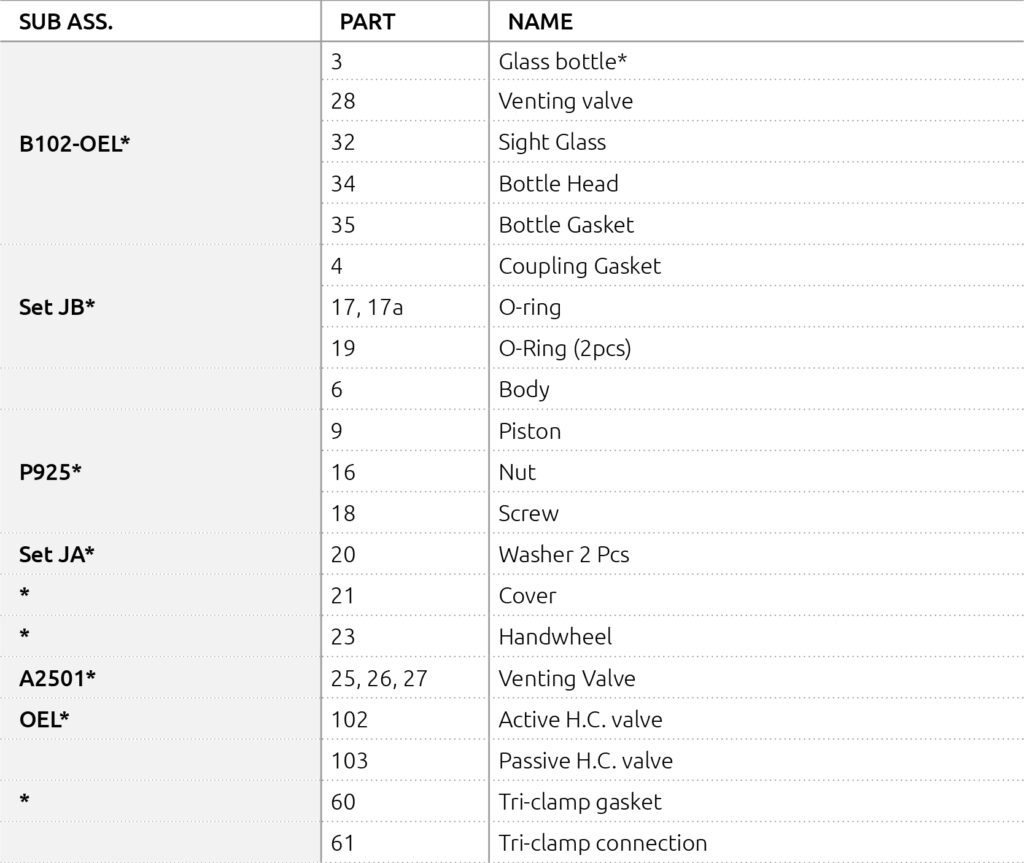

125TC

TRI-CLAMP EASY-CLEAN VALVE

This sampling valve has one 2.5” Tri-Clamp (TC) near the handwheel (Fig. 1). It is called easy-clean because the piston can

be removed from the valve housing with minimal effort (Fig. 2), allowing full cleaning of inner surfaces of the valve’s

body between batches.

125TC-OEL

HIGH CONTAINMENT VALVE

This new compact OEL High-Containment sampling device (Fig.1) enables the removal of the sample under contained

conditions. The OEL (Occupational Exposure Limits) describes the maximum concentration of a hazardous substance

which can be tolerated in the air of the production room without any negative effect to the health of the operator

(Fig.2).

OEB (Occupational Exposure Band) : OEB4 1-10 μg/m3

125TC-OEL

HIGH CONTAINMENT VALVE

This new compact OEL High-Containment sampling device (Fig.1) enables the removal of the sample under contained

conditions. The OEL (Occupational Exposure Limits) describes the maximum concentration of a hazardous substance

which can be tolerated in the air of the production room without any negative effect to the health of the operator

(Fig.2).

OEB (Occupational Exposure Band) : OEB4 1-10 μg/m3

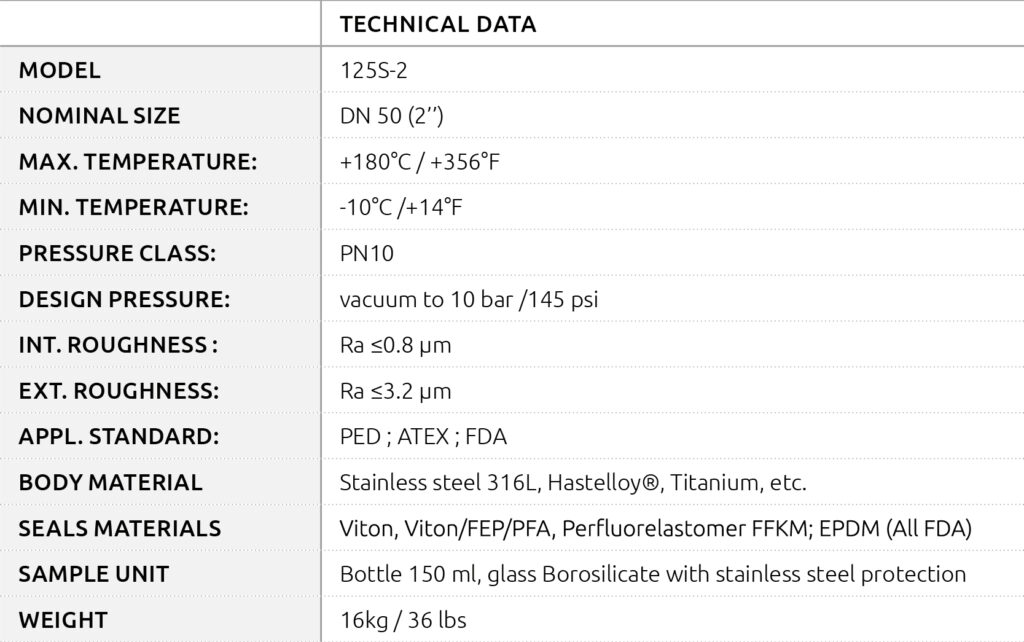

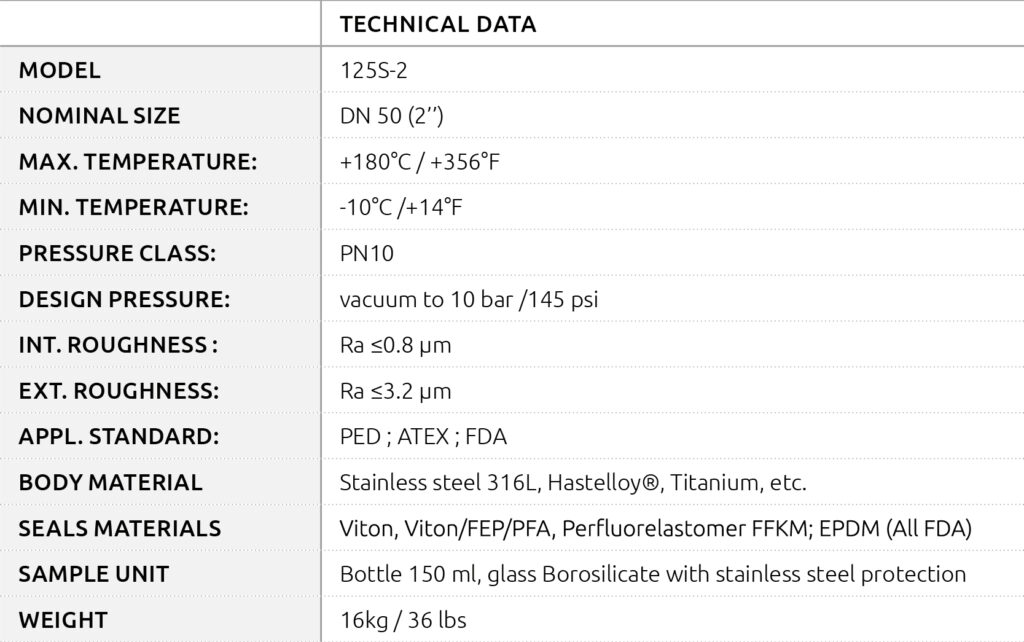

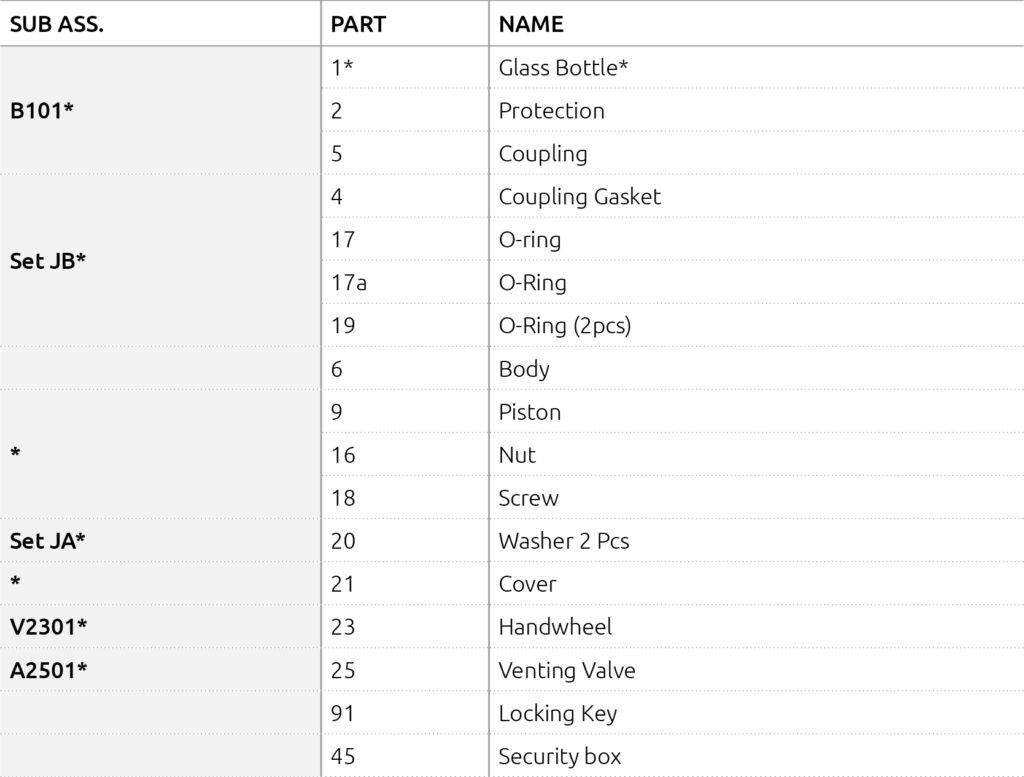

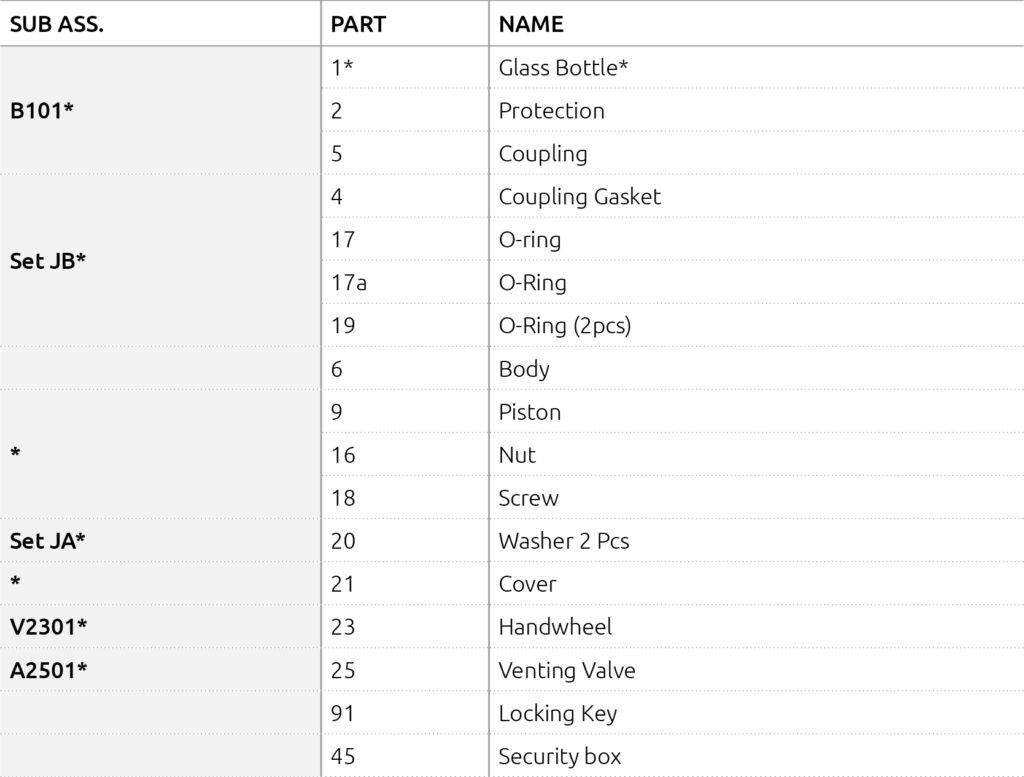

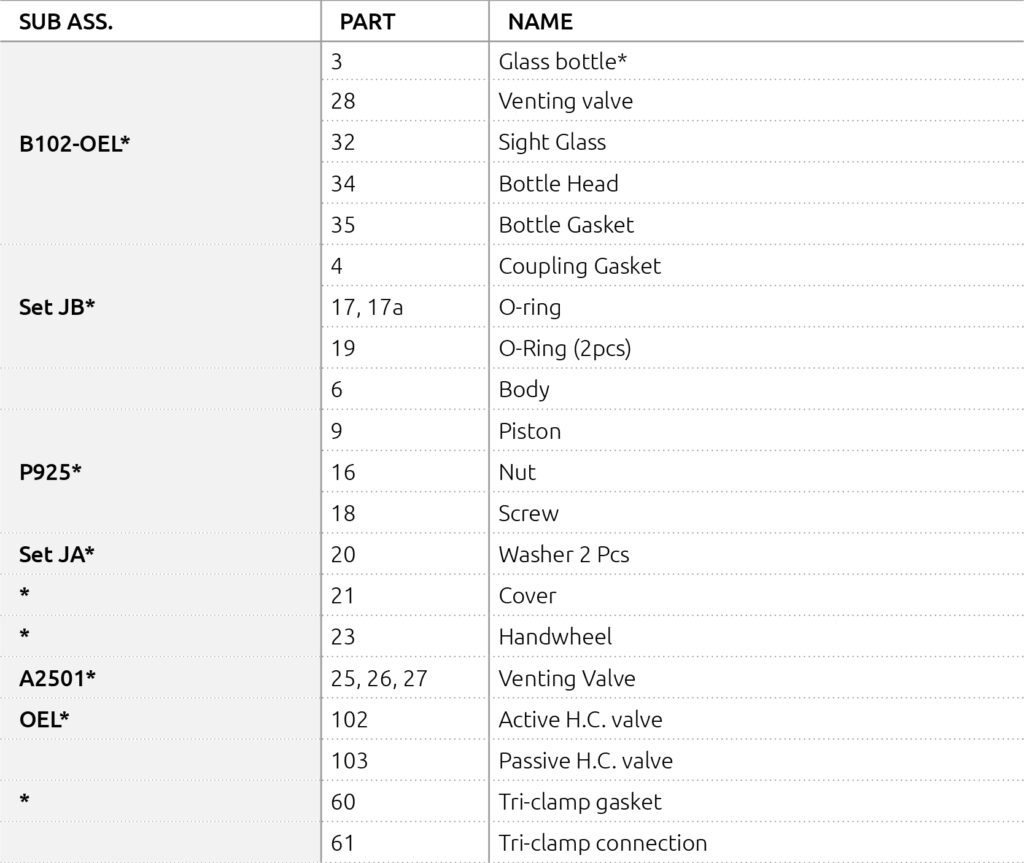

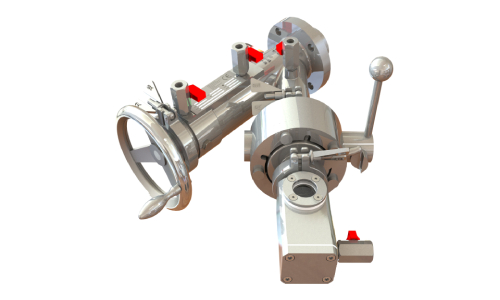

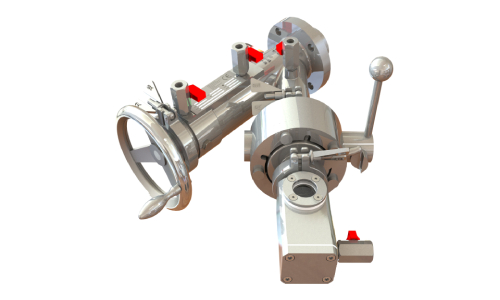

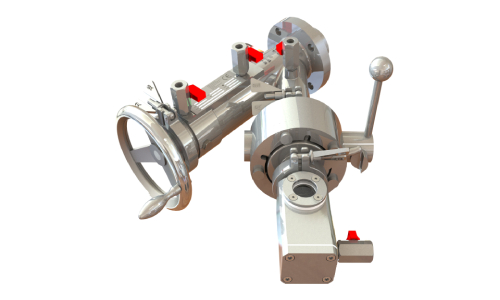

125S

SECURITY VALVE

The mechanical locking device secures the sampling procedure.

1. The sampling bottle can only be removed if the piston is completely closed.

2. The piston can only be opened if the sampling bottle is coupled to the outlet.